Address

Unit 49, Space Business Centre

Molly Millars Lane

Wokingham, Berkshire

RG41 2PQ, UK

Opening Times

Mon - Thu: 08.30 - 17-00

Fri: 08.30 - 14.00

Brochure

Newstar Bespoke™ is a personalised service allowing customer-specific parts to be manufactured or standard parts to be adapted to meet individual customer requirements. Such processes are available thanks to worldwide relationships forged with several key manufacturers located around the globe and the vast fastenings experience in our procurement team.

Newstar Bespoke™ examples are detailed below:

Cannot see what you require on our website or in the market? Newstar Bespoke™ can help by providing a service that allows customer-specific, non-standard parts to be manufactured or altered to mirror end-user requirements.

Whether the item is made to a drawing, to specific dimensions, or a non-standard material a requirement can be made to mirror demand. Simply email a request and within 24hrs a quote can be conveyed*

*Subject to minimum manufacturing requirements.

Newstar offer a variety of bespoke screw manufacturing procedures. Our two most common processes are listed below:

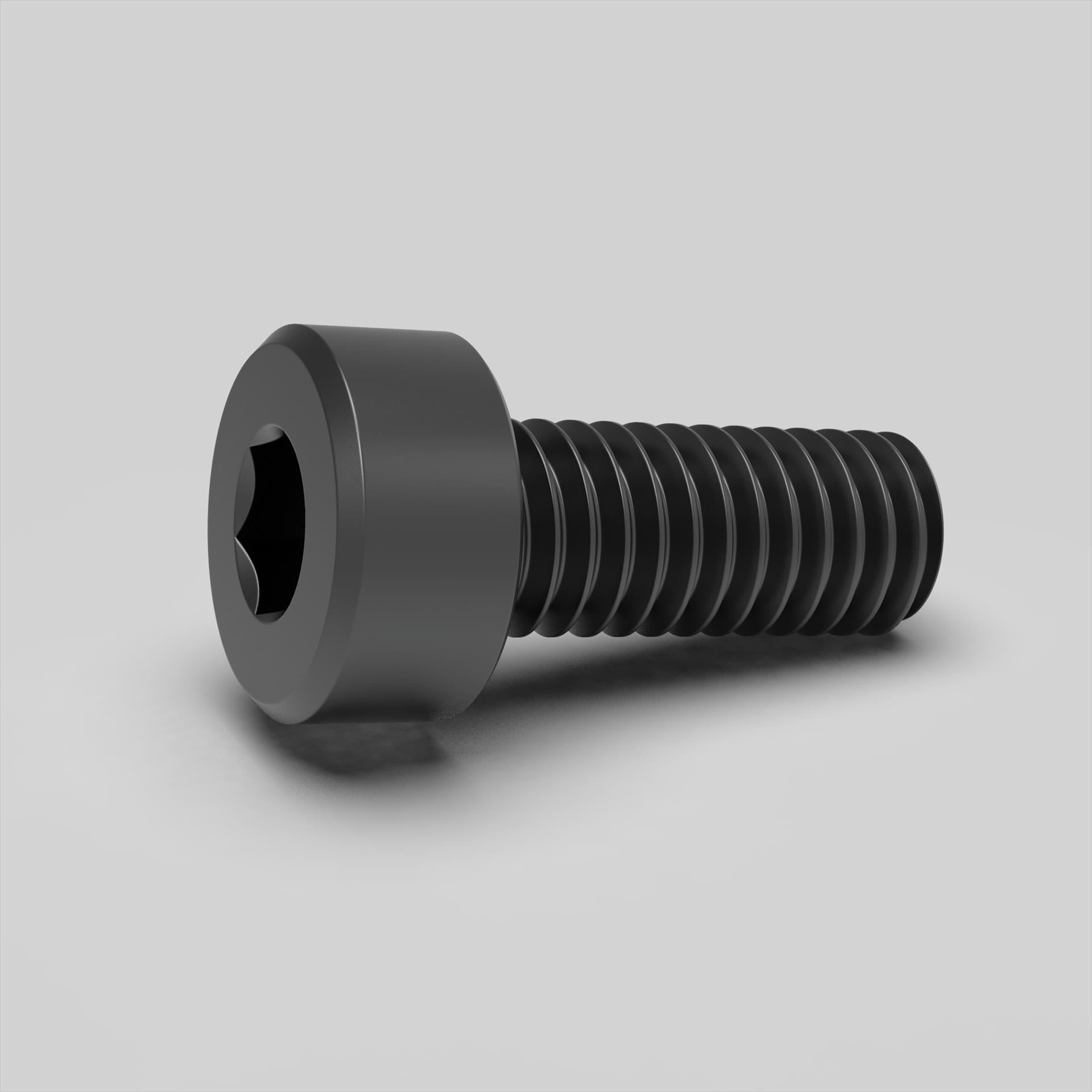

Cold Forged

A manufacturing technique using a cold working process that squeezes the material into a die before the parts assume the shape of the die. From this, an additional cold headed process forms the screw features such as the knurls or drive of the screw. The thread of the screw is then rolled on the screw shank.

Advantages of such a process are:

- Superior surface finish.

- Accuracy in dimensional control.

- Improved reproducibility and interchangeability.

Bar Turned

A manufacturing technique using rotating machinery which involves the cutting or removal of complex predesigned shapes and thread forms. This process is commonly manufactured using a CNC/ Single or Multi Spindle bar turning machines.

Advantages of such a process are:

- Easier to manufacturer medium to low volume quantities.

- Ideal for high precision and complex machined parts to DIN/ISO spec or customer drawings.

- Ideal for high end/ aesthetic fastener appearance.

Newstar Bespoke™ offers a wide range of alternative materials/ surfaces which may not be listed from stock on our website. Please see our full material capabilities below:

Materials

Steel: AVP, AVZ, 100Cr6, SEA1018

Stainless Steel: AISI 303, AISI 304, AISI 316L, AISI 316LS, AISI 316LM, AISI 420, AISI 430.

Titanium: Grade 2, Grade 4, Grade 5, Beta Titanium.

Nickel Alloy: Nickel Silver, Brass, Bluebrass, Ecobrass, Bronze.

Aluminium: A2011, A6024, A6060, A6075, A6082, A7075.

Surfaces

Coating: Anodizing, silver plating, chromium plating, pickling, gilding, gold plating, nickel-free treatment, thread lock, polish, nickel plating, copper plating, tinning, zinc surface.

Hardening: Quenching, case hardening, nitriding, solubilization, hardening.

The Black Oxide (also known as Blackening) service provided by Newstar Bespoke™ offers an alternative appearance to any stainless steel, alloy steel items. Such a treatment provides the following benefits:

Unable to source the fastening you require in the correct finish? Newstar Bespoke™ provides a Strip and Replate service allowing such issues to be resolved. Bespoke plating services include:

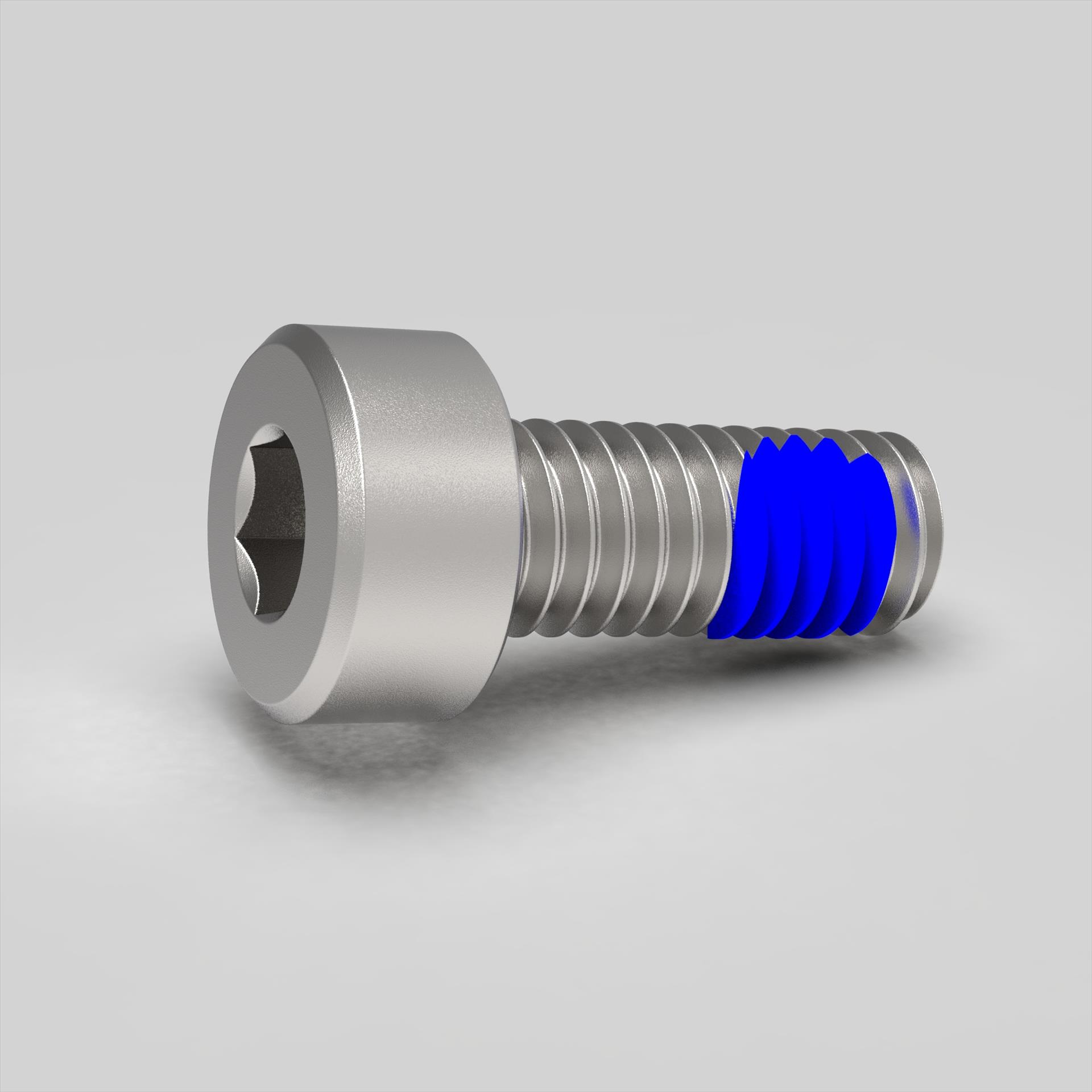

Having issues relating to vibration, loose screws, or loading at the assembly phase? A pre-applied Nylon Patch is a common preventative action. Newstar Bespoke™ offers such a solution thanks to its key links with specialists in the UK and further afield.

Whether you require a 180˚, 360˚, Horizontal or Vertical patch such a service provides the following advantages:

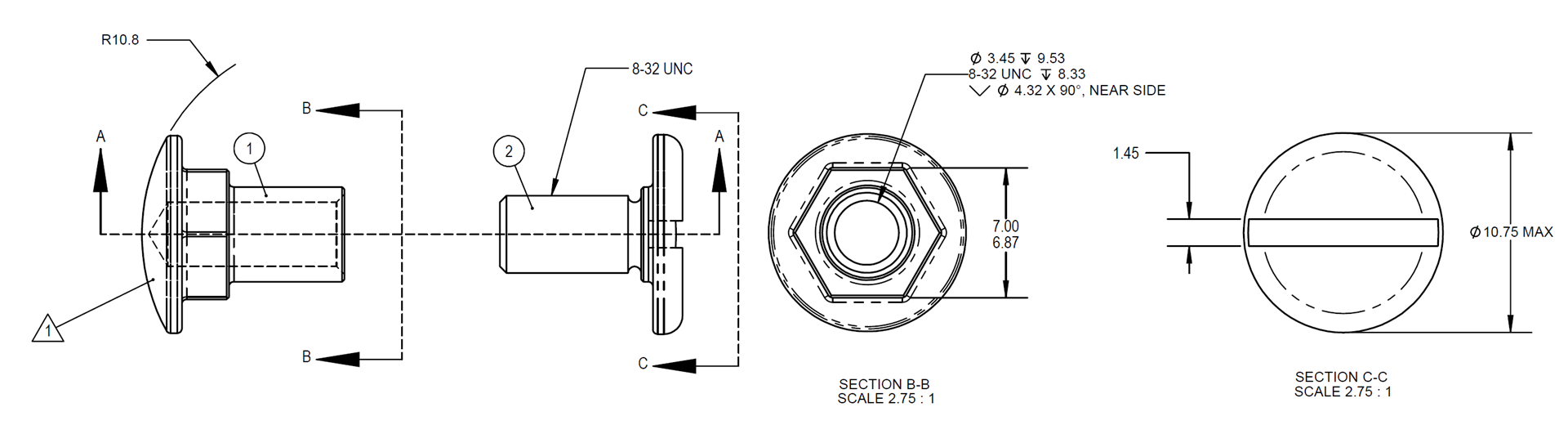

Having issues with screw retention? A popular option often used to eliminate such problems is to captivate the screw thread. A captive screw is manufactured/ altered by adapting a threaded section so a thread is reduced to its core/ a customer-specific diameter.

Benefits for such a procedure include:

- Securing a component in a fixed position.

- Reduced screw cost from damage or loss.

- Can be implemented using different styles or materials offering great variety.